Digital Hybrid Packaging Solutions for Wisconsin and Midwest Brands

QPI’s digital hybrid packaging solutions merge the strengths of traditional flexographic and digital printing to deliver exceptional quality, speed and flexibility. Our hybrid process empowers Wisconsin and Midwest brands to produce packaging with precise color control, variable data options and quick turnaround, all while maintaining cost efficiency and sustainable production standards

Combining Precision and PerformanceDigital Hybrid Printing Technology

QPI’s hybrid printing systems unite flexographic efficiency with digital versatility to produce high-value packaging at any scale. Our approach enables fast setup, minimal waste and detailed graphics without the cost barriers of fully digital runs. With digital hybrid packaging, brands can create short-run or large-scale packaging projects that maintain consistency across every print cycle.

Enhancing Customer Engagement

Digital hybrid packaging elevates customer engagement through tactile design and personalized experiences. QPI’s printing capabilities include embossing, debossing and textured coatings to enhance the sensory feel of each package. Variable data printing adds personalization, allowing brands to include unique promotions and regional messages.

From unboxing experiences to retail shelf appeal, digital hybrid packaging helps brands stand out while deepening their connection with customers.

Maximizing Return on Investment (ROI)

QPI’s hybrid printing approach helps brands reduce setup time, tooling and material waste, lowering total production costs without compromising quality. Our Wisconsin-based production facility supports just-in-time delivery to minimize inventory overhead while providing fast response to market trends.

Digital hybrid packaging solutions deliver measurable ROI by improving efficiency, enabling faster updates and creating more sustainable workflows for packaging design and production.

Sustainable and Eco-Friendly Packaging

QPI’s digital hybrid packaging process supports sustainability through reduced ink usage, optimized substrate application and streamlined production workflows. We leverage hybrid printing to minimize waste and energy consumption while using recyclable materials across a wide range of packaging types.

Our environmentally conscious practices help brands meet sustainability goals without sacrificing durability, print quality or visual appeal.

Seamless Integration with Digital Workflows

QPI’s digital hybrid packaging solutions integrate seamlessly with modern digital workflows. Our systems work with your existing design files and digital assets to accelerate setup, automate color management and guarantee consistent results from concept to final production.

Real-time quality checks and automation deliver reliable precision on every run, giving brands prints consistently reflecting their identity and standards.

Next Generation: Kento Hybrid Printing Technology

The Core of Our Digital Hybrid Process

QPI’s Kento Hybrid system represents the next generation of digital hybrid packaging, combining flexographic strength with high-definition digital detail. This single-pass system delivers unparalleled flexibility, enabling brands to print vibrant graphics, crisp text and durable finishes on a wide range of substrates.

-

Total Cost & Speed: Reduced tooling, inline die cutting and shorter turnaround times create a just-in-time production model for retail packaging

-

Sustainability: Lower ink consumption and efficient production cycles reduce environmental impact

-

Versatility: Supports a variety of materials, from lightweight paperboard to heavy corrugated displays, offering endless creative possibilities

-

Quality: Achieves the best of both worlds: solid flexo backgrounds with digitally printed, high-resolution graphics for unmatched clarity

-

Flexibility: Adaptable to evolving job requirements, enabling late-stage design adjustments and promotional customization

-

Personalization: Delivers targeted packaging opportunities through variable data printing for seasonal or retailer-specific campaigns

Hybrid Kento Press Applications:Advancing Digital Hybrid Packaging

Kento Graphic Development

Flexo Plate

Uses cost-effective inks for solid backgrounds, reducing expenses compared to fully digital printing

Digital Image

Provides high-definition graphics and accurate color matching for polished, professional packaging

Hybrid Results

Offers unmatched versatility for seasonal promotions and rapid design updates

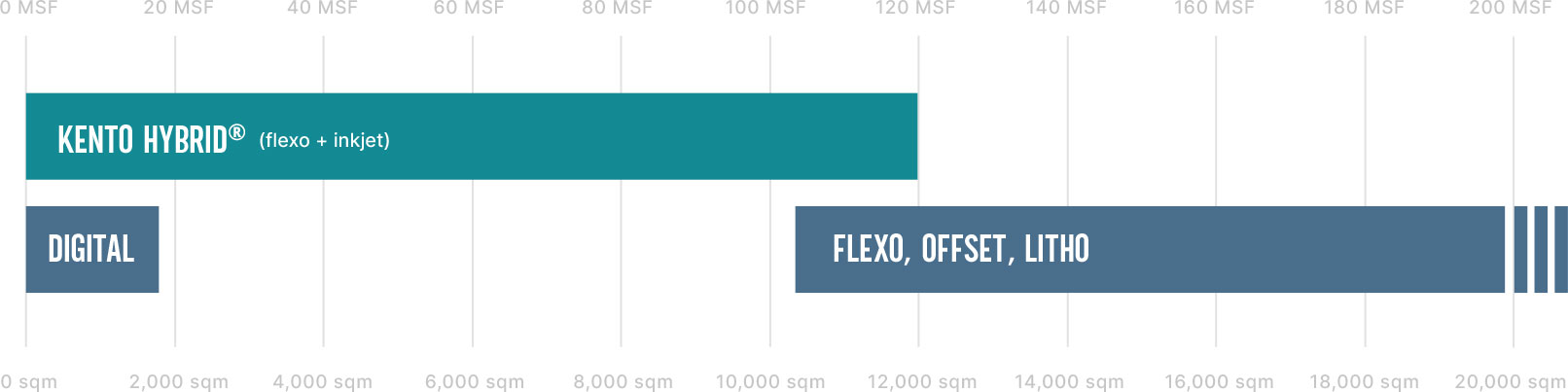

Kento Hybrid® Bridges the gap

-

Kento Hybrid®

The best of both worlds, digital + flexo, designed and built for printing on corrugated. Unbeatable in small, mid-sized and some large orders.

-

Flexo

Expensive Plates, Low cost ink, longer setup and downtime. Great for big orders

-

Digital

No plates, expensive ink, short setup time. Great for small orders

Targeted POS Signage with Compliance

Targeted POS Signage with Compliance

Direct Mail

Direct Mail

In Store Merchandising with Customization

In Store Merchandising with Customization

Direct to Customer

Direct to Customer

First Party Shopper Engagement Data

First Party Shopper Engagement Data